Mold

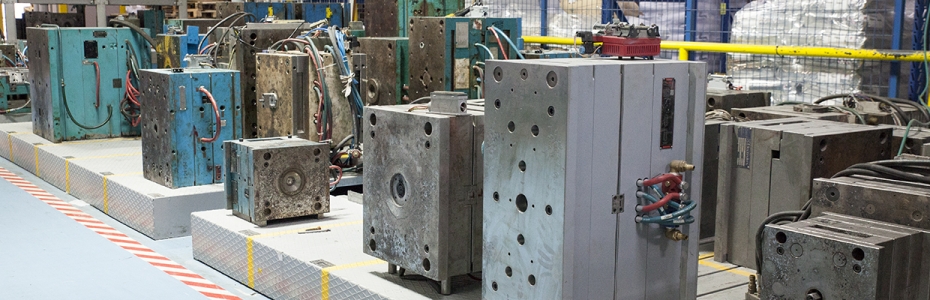

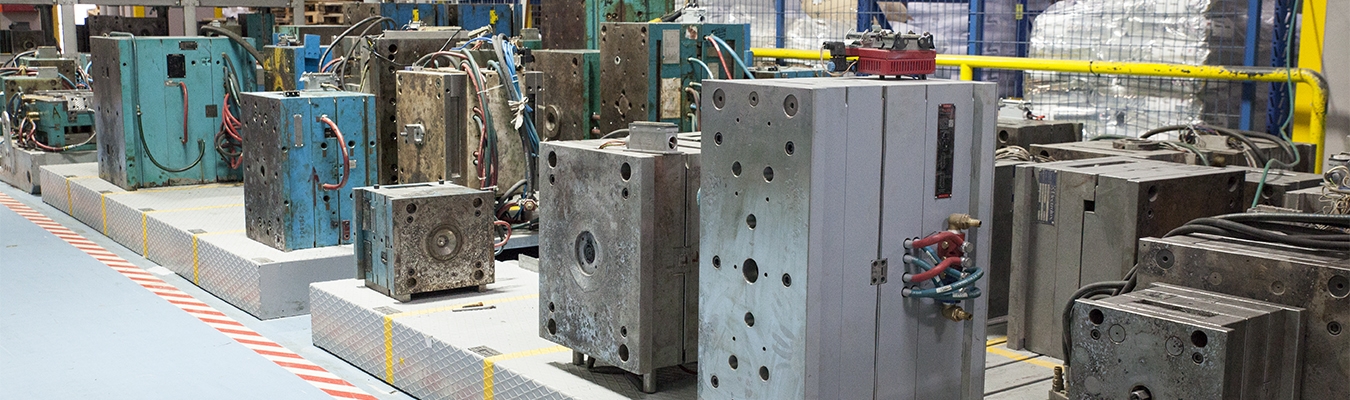

We at Alpplas believe that the skill of mold design and production is crucial for the uninterrupted production of plastic components. Therefore, we have been designing and manufacturing such molds needed by our companies for many years. We internally manufacture a various sizes of molds from gas injection, IML molds to those used in 8,000 kN injection machines in our central molding room within the organization of our Bolu Plastics Business.

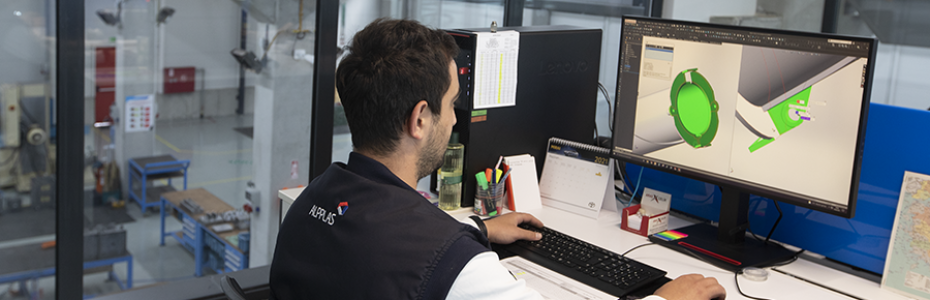

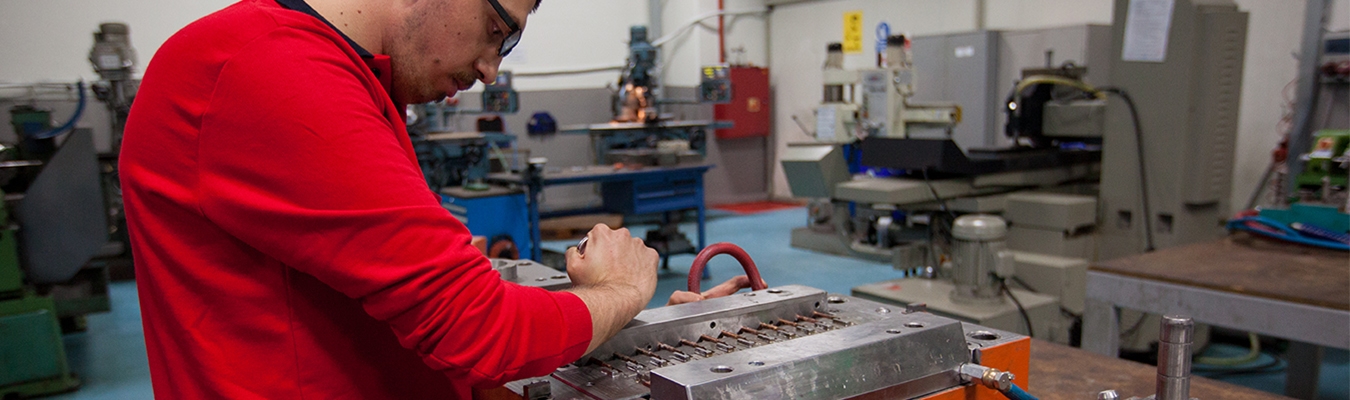

Design is the most important stage of a perfect result to deliver. Therefore, we make use of the most advanced design and analyses programs and, mix them into our experience of 30 years. What makes us different from standard mold manufacturers is that we are living in and aware of the mass production conditions for molds. In addition, the ability to be involved in the design process of our customers provides a saving for time and resources during the performance of project processes.

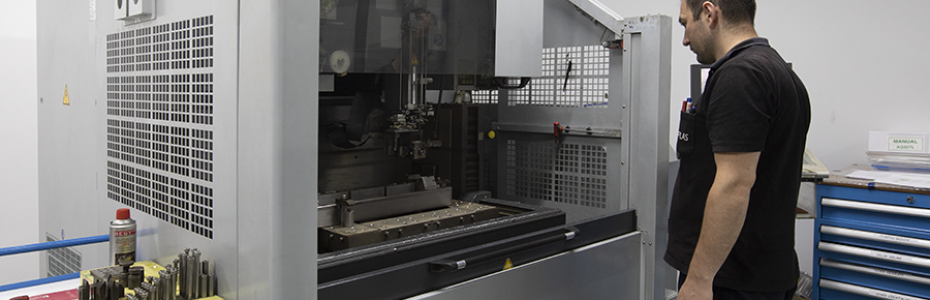

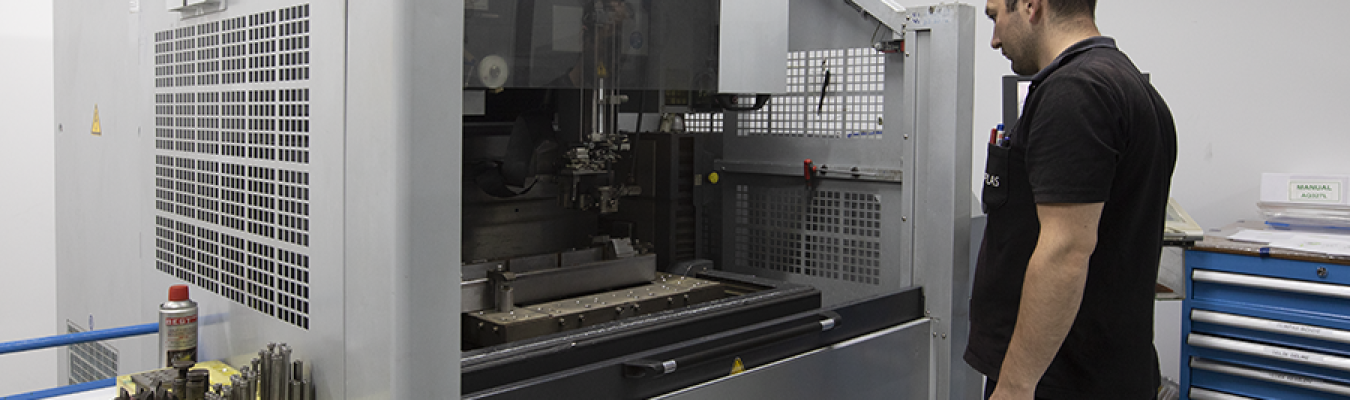

Projects approved in respect of design are transferred to the project and production department and, the material supply processes and part machining processes are carried out in parallel. The fact that all the mold production processes take place in a central molding room means that the sources are used in the most optimum manner for all the project stakeholders.

Parts manufactured are collected in the mold collection department together with the electrical components such as hot runners and valve gates and, made ready for the first printing. Thanks to the extensive machinery park of Alpplas, all printing process for all the molds manufactured including the final testing take place internally, unlike many other mold manufacturers. Together with all the respective measurements reports thanks to the 3d metrology room available in our organization, the parts are accordingly delivered to our customers.