Electronic

We started to manufacture electronic products in 2002 and, continue to enlarge the extent of this production improving our capabilities year by year. We offer our customers from various industries a large variety of solutions starting from the design stage thereof.

With 7 separate SMT lines in total located in two different locations, we are capable of manufacturing the card designs of even the most complex cards without any problem and, with the principle of zero error. Thanks to our machinery line design, we are capable of not only mass production with a large number of products, but also small batch productions with the least losses and at competitive costs for our customers.

With the in-line 3D SPI (Solder Paste Inspection) automatic solder control systems available in our lines, we are capable of providing cream solder checks before the component assembly.

In all of our lines, we can reach high component sorting capacity with Pick & Place machines belonging to the world's leading brands in the field of electronic sorting, such as Panasonic and Samsung.

After the components are assembled, we are also able to provide quality control of electronic printed circuit boards with cameras and automatic image processing systems, thanks to in-line AOI (Automatic Optical Inspection) machines.

With AXIAL and RADIAL typesetting machines used for component typesetting, we are capable of eliminating the need for manual assembly while keeping efficiency and product quality at the highest level.

Thanks to the IC Programming machine, we can apply the software process on the PCB after SMT typesetting.

With our PBT MiniSwash machine, we offer high-level washing and drying solutions through specially developed detergents for all kinds of parts that require washing in the electronics production field, such as stencils, PCBs, PCBs and squeegees.

While we aim to automatically arrange the highest number of components in our electronic production, manual sorting processes are also an indispensable process for electronic production due to different needs. For this purpose, we can also type TH components with different sizes and structures on our manual typesetting lines.

We offer RoHS compliant high soldering standards with Kurtz Ersa and SunEast nitrogen wave soldering (Wave Soldering) machines and Kurtz Ersa nitrogen local soldering (Selective Soldering) machine.

Thanks to the Router device we use for PCB and PCB, we are able to separate the cards from the panel with 100 micron precision and minimum stress values.

We are also capable of make use of the automatic and manual systems designed within our company to carry out the cabling and plastics grouping-assembly works for the cards manufactured

Protective coating (conformal coating), which has been a very critical issue in automotive electronics in recent years, is becoming increasingly widespread in white goods and other industrial sectors. Conformal coating provides protection against environmental conditions such as moisture, dust, salt and oxidation in electronic cards and contributes to the long-term usability of the electronic cards.

Accordingly, our company, acting in cooperation with a world-leading brand in coating with more than 25 years of experience, is capable of carrying out coating applications to the surface of printed circuit boards selectively, without requiring masking, in the Conformal Coating process.

It is our consistent aim that we want to keep the quality of the services we offer to our business partners at the highest level at all times. For this reason, in terms of packaging, we can manufacture ESD-compliant blister (Thermoform) that can be used in the transportation and shipment of electronic cards with the blister machine we produce and develop in-house. Thanks to the machine molds we design within our business, we are capable of producing blisters in any size. Through the anti-static material we use, we prioritize product safety for our local and international customers, taking into account all the risks that may occur during the shipment of electronic cards.

In our test control department, we perform ICT and FCT tests on PCB. With the talent and experience of the Alpplas R&D team in this field, we can design ICT and FCT testing machines, devices and fixtures specific to each product. In this way, in addition to saving time and cost for each project to be commissioned, we also provide advantages to our customers in terms of product safety and quality.

We are also able to meet traceability requirements on a process basis and, provide test reporting and analysis for each product.

In addition, we can develop applications for camera-controlled systems for lighting cards and image processing systems that are capable of providing component control on PCBs. We adapt FCT test systems to PLC-based, pneumatic systems, independent of the human factor, and we are able to control the elements of electronic cards such as voltage, current, power, frequency, duty cycle, brightness and color, character recognition, voice recognition, pressure measurement and motion control.

Laser marking process applications on PCB, which is a basic requirement for traceability systems, can be performed in our company. Attaching importance to the requirements in this regard, our company can also produce laser marking machines within its own structure, thanks to its R&D efforts.

Alpplas is capable of tracing each component from the arrival thereof to the factory to the departure thereof from the factory as a finished product. Using the factory solution of Panasonic PanaCIM, our company closely follows the developments and trends throughout the world. With its investments and R&D efforts in traceability systems, it is able to provide traceability system integration in the existing production lines. It also offers applications for flow traceability, reporting and analysis of test results in the test processes for PCBs after SMT production accordingly.

At the same time, Alpplas is capable of developing and implementing systems that provide instant monitoring of both machine capacity usage and line efficiency with the Alp-Asist system, which works integrated with its own production machines or lines.

In order to constantly keep the quality of the services we offer at the highest level, we always prefer the most advanced technology and highest level production machines and devices in our investments. We are also able to manufacture machinery and devices in our company. Here is the list of the machinery park available in our company.

SMT Production Lines;

- Laser Marking Devices,

- SMT Typesetting Machines,

- In-line AOI and SPI Devices,

- Ovens,

- Axial, Radial Machine,

- IC Programming Machine,

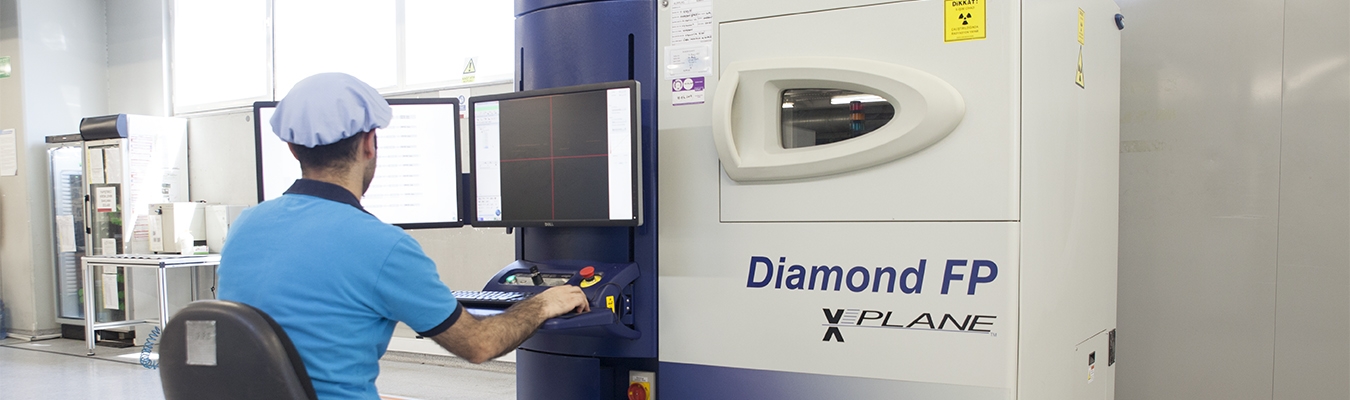

- X-ray Inspection Machine,

- PCB Washing Machine.

THT Production Lines;

- Nitrogen Wave Soldering Machine,

- Nitrogen Local Soldering Machine,

- Off-line PCB Router Machine,

- Conformal Coating Machine,

- Testing, Assembly Devices,

- Camera Control Systems,

- Blister (Thermoforming) Machine,

Use of technology in the production of electronic components is important for all the processes from the incoming quality control to the delivery of products in addition to the production stage. Thanks to our expensive incoming quality control laboratory, we make sure that each component and product supplied fulfills the defined characteristics and performances. For many products and components, we save time and cost by means of conducting many validation tests in our own laboratories such as cross section (bakelite), fireproofing test, ball pressure, glow wire, tracking, dust measurement, stress measurement, spectrophotometer, pollution test, XRF element analysis.